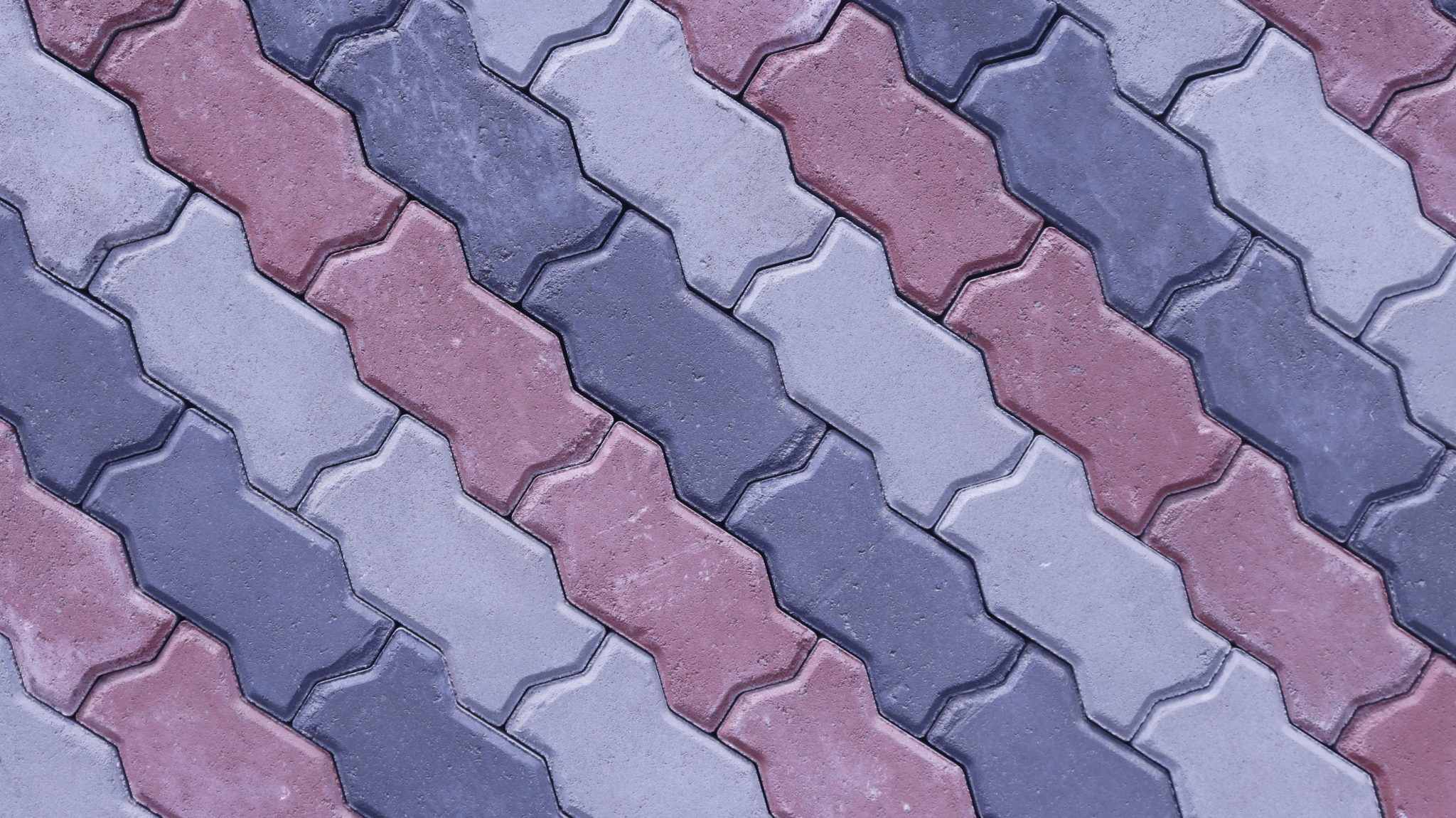

Q-Bricks, a unit of Nalakath Granites ventured into the Cement Bricks business in the year 2016 and currently operates as one of the largest units in Kerala with Brand Name “Q-Bricks”.

A concrete block is primarily used as a building material in the construction industry.

A concrete block is one of several precast concrete products used in construction.

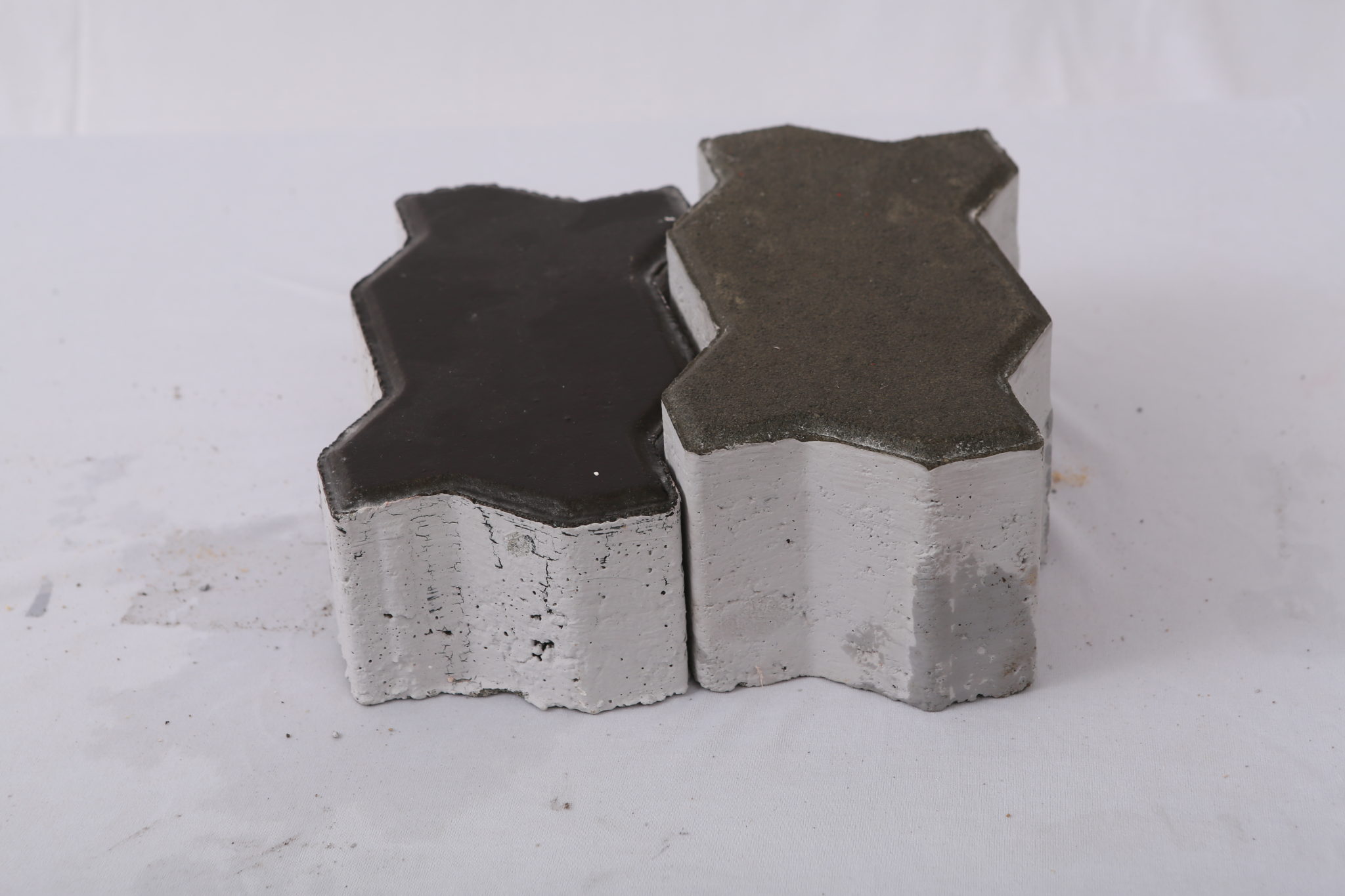

The term precast refers to the fact that the blocks are formed and hardened before they are brought to the construction site.

Most concrete blocks have one or more hollow cavities, and their sides may be cast smooth or with a design. In use, concrete blocks are stacked one at a time and held together with fresh concrete mortar to form the desired length and height of the wall.

Q-Bricks has one of the most high-tech blocks manufacturing technology in Kerala. Concrete block manufacturing is a highly automated process that can produce up to 20 pieces of bricks per hour and 30 pieces of pavers per hour.

A concrete block is primarily used as a building material in the construction industry.

A concrete block is one of several precast concrete products used in construction.

The term precast refers to the fact that the blocks are formed and hardened before they are brought to the construction site.

Most concrete blocks have one or more hollow cavities, and their sides may be cast smooth or with a design. In use, concrete blocks are stacked one at a time and held together with fresh concrete mortar to form the desired length and height of the wall.

Q-Bricks has one of the most high-tech blocks manufacturing technology in Kerala. Concrete block manufacturing is a highly automated process that can produce up to 20 pieces of bricks per hour and 30 pieces of pavers per hour.

Quality construction continues to be a challenge in the construction industry. Nalakath Group understood this need in the market and began Q-mix in the year 2016.

Today, We are one of the largest manufacturers of Bricks in Kerala for the construction industry.

Constructions of varying size opt Q-bricks and other Nalakth products for their construction needs. Q-bricks is part of Nalakath's journey to excellence and success. Set up in Perinthalmanna, Kerala, We have with our state of the art machinery which help us build quality products.

This unit has taken a lot of measures towards a sustainable future. The following are the raw materials used in the manufacturing of concrete blocks at Q-bricks :

These grades of cement are ground much finer which imparts more durability and strength to the cement.

Today, We are one of the largest manufacturers of Bricks in Kerala for the construction industry.

Constructions of varying size opt Q-bricks and other Nalakth products for their construction needs. Q-bricks is part of Nalakath's journey to excellence and success. Set up in Perinthalmanna, Kerala, We have with our state of the art machinery which help us build quality products.

This unit has taken a lot of measures towards a sustainable future. The following are the raw materials used in the manufacturing of concrete blocks at Q-bricks :

- Cement: OPC 53 Grade

These grades of cement are ground much finer which imparts more durability and strength to the cement.

- Fine aggregate: Q-sand

- Coarse aggregate: 6mm & 12mm metal.

At Nalakath, We emphasize a lot on Quality standards. Hence we go an extra mile when it comes to ensuring that quality products are delivered without making any compromise on on-time delivery

- RAW MATERIALS:-

We perform a daily assessment on the quality of raw materials and their conformation to IS Standards. We check the physical properties of aggregates like sieve analysis bulk density flakiness index, elongation index, impact value, crushing value, specific gravity etc.. and ensure that it is of very high standard and superior quality. - MIX DESIGN:-

Based on the physical properties of aggregates, appropriate mix proportions (by weight) will be derived. This will ensure that good quality blocks are produced or manufactured with a smooth finish and one that has a texture with high compressive strength, low water absorption - BATCHING PLANT:-

We have with us batching plants that are fully automated. We also perform periodical calibration of pan mixer that provides consistent quality concrete mixing. - BLOCK MAKING PLANT;-

We use imported Block Making machines which is of superior quality. Our plant is imported from Beijing, China and is manufactured by Beijing REIT Technology Development Co. Ltd., which is a professional integrated company in developing, manufacturing, selling and providing services. REIT has followed through Total Quality Control and passed ISO9001:2000 quality system certification and CE certification. Using this technology, we are able to manufacture good quality concrete blocks with high compressive strength, high vibration and compression, precise measurement of dimension, improved corner finishes and surface finishes. -

CURING:-

Curing of concrete entails providing adequate moisture, temperature, and time to allow the concrete to achieve the desired properties for its intended use. We perform effective curing system which ensures that each and every block is properly cured thus ensuring the quality of our products. - EFFECTIVE QA/QC SYSTEM:-

Periodic online checks at the green and dry stage help us to maintain high-quality products. Periodic checks ensure that the issues are identified at the early stage. We have an in-house testing facility to check compressive strength, density, water absorption, measurement of dimension etc.

Some of the benefits of working with us are as follows :

- 1. We are a customer-centric organization. We put the needs of the customer above everything. Hence our team of specialists will learn more about your requirements and provide you with a solution that is most suitable for your construction needs.

- 2. As our name suggests, We emphasize a lot on "Q". Q represents Quality. At every process of our development, we ensure that the products manufactured are of high-quality standards.

- 3. We have professional millers who ensure that the products are transported and delivered to the customer site.

- 4. Our highly skilled engineers provide you with consultancy services to choose the solution that is best suited for your construction needs.

- 5. We use state of the art technology at our organization which ensures quality products in optimal time with best prices.

We would love to hear from you more on your requirements. We work from 8 AM to 6 PM Monday through Friday. For any further inquiries, Please contact us in the following numbers: (+91)-7034008800 / (+91)-9645006300